Facilities

Melting Furnaces

Eight (8) units of melting furnaces, each of 25 metric tonnes capacity that is linked to heat regenerating burner systems and magnetic stirrer that can enhance energy conservation

and increase productivity.

Holding Furnaces

One (1) unit of 30 metric tonnes hydraulically tilting holding furnace for better control of melt temperature, which improves product quality and productivity.

Homogenise Furnaces

Five (5) units of 35 metric tonnes homogenising furnaces with three (3) units of air cooling booths.

Casting Facilities

Four (4) units of fully automated vertical direct chilled hydraulic controlled casting system.

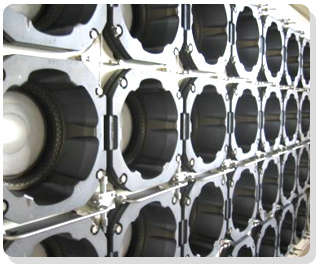

Billet Molds

Wagstaff AirSlip Air Casting Process Mold

Aluminium billets cast with Wagstaff “Airslip” billet casting mould system have a shallow molten metal sump and a thin-shield, uniform-grained composition that is beneficial to the extrusion process.

Hot Top Mold

Hot Top Molds forms the support system.

In-Line Degasser

In-line degasser to remove dissolved hydrogen in molten aluminium hence improving the aluminium billets quality.

Billet Sawing Machines

Seven (7) units of billet cutting saws to shorten the cutting process and thus ensure speedier delivery of products.

“An eye for Quality Control”

Through close interaction with our customers, we deliver Quality Products that not only meet but exceed their expectations

Light Emission Spectrometer

Two (2) units of Light Emission Spectrometer to verify the alloy composition of the molten metal during the entire casting process.

Alscan Hydrogen Analyser

One (1) unit of Alscan Hydrogen Analyser. AISCANis a reliable quantitative technique to directly monitor the dissolved hydrogen content in molten aluminum. This technique is fast, accurate over a broad measurement range and offers outstanding reproducibility. The AISCANis recognized by the industry worldwide.

Ultrasonic Testing

Ultrasound Fault Detector to check all billets for internal cracks and faults

Optical Microscope

Optical Microscope to determine the quality achieved in the casting and homogenizing process from aluminium samples taken for metallurgical studies.